Written by Kara Fritze, Kasco Municipal Sales Territory Manager – Western US

Unchanging and predictable water quality is key to a well-run distribution system. Active mixing is a solution that improves and controls water quality in distribution systems. Reasons to use an active mixer in your water supply system are limitless, but we’ve narrowed down the top 10 here.

1. Eliminating Thermal Stratification

In summer, the water in an unmixed water tank begins to warm. The warmer water rises to the top. When newly treated denser, cold water enters, it doesn’t mix with the warmer water in the tank. Instead, the cold water will fall to or remain at the bottom of the tank water column, depending on the inlet structure. This cold bottom water can also be the first to exit the tank, leaving the bulk of the warmer top water unmixed and unused. This process, called stratification, causes many problems in water tanks.

Before and after images showing the thermocline layer

eliminated by Kasco’s CertiSafe™ Tank Mixer

2. Eliminating Chemical Stratification

Seasonal and ambient temperature changes can be especially difficult to control the chloramine process as well as maintaining a free chlorine residual in unmixed water storage tanks. The best way to maintain a free and combined chlorine residual is through active mixing.

3. Reducing Chlorine Residual Loss

Thermal stratification leads to chemical stratification that can seriously compromise water quality. The upper layer contains the oldest, warmest water with low disinfectant residuals. This can lead to bacteriological contamination and high concentrations of disinfection by-products. The warm conditions at the air-water interface on the interior sidewall allows biofilms to prosper. This increases organics in the water and contributes to corrosion of the tank wall.

4. Reducing Differences in Water Taste and Odor

Water age can greatly impact the taste and odors associated with stored water. The best way to reduce taste and odor concerns is to make sure that the full volume of a water storage tank is completely mixed. This will provide a consistency in the taste and reduction of chlorine odor in the water.

5. Reducing Nitrification Risk in Chloraminated Water

Testing by several water agencies has proven that nitrification issues can be greatly reduced and more often than not, eliminated by actively mixing the water inside of a water storage tank.

6. Lowering the Rate of Disinfection By-Products

In a stratified water tank, several factors can lead to high organic loads in the water. Reactions of chlorine with organic matter lead to the formation of disinfection by-products (DBPs). DBPs can be detrimental to human health and are regulated under the Safe Drinking Water Act.3

7. Preventing Ice/Freezing and Corrosion

During winter, ice forming in a water tank scrapes interior tank fittings and coatings as the water levels change from daily fill and drain cycles. Overflow issues tend to be solved with proper maintenance. Static water conditions, however, can be impacted by operational measures. Freezing can cause internal piping and overflow breaks, ladders to be pulled out by ice leaving a hole at the point of attachment, hoop stress loads on the steel and seams from expanding ice, and ice damage to the tank lining, allowing corrosion.

8. Lowering Rate of Sediment Accumulation

Mixing a storage tank with a powerful active mixer will keep sedimentation in suspension and provide the system operator with the ability to remove the sediments through flushing those deposits out the distribution system through fire hydrants and system flush valves rather than allowing it to build up and harbor harmful bacteria inside the tank. Tank cleaning schedules can be extended thus reducing the cost of periodic tank cleaning.

9. Keeping Your Tank Mixed, 24 Hours a Day, 7 Days a Week

Will allow the system operator to maintain a higher water level inside the water storage tank and increases the ability to maintain adequate levels for fighting fires. Maintaining a greater capacity of stored water also help reduce the ISO ratings and help keep insurance rates down for the rate payers.

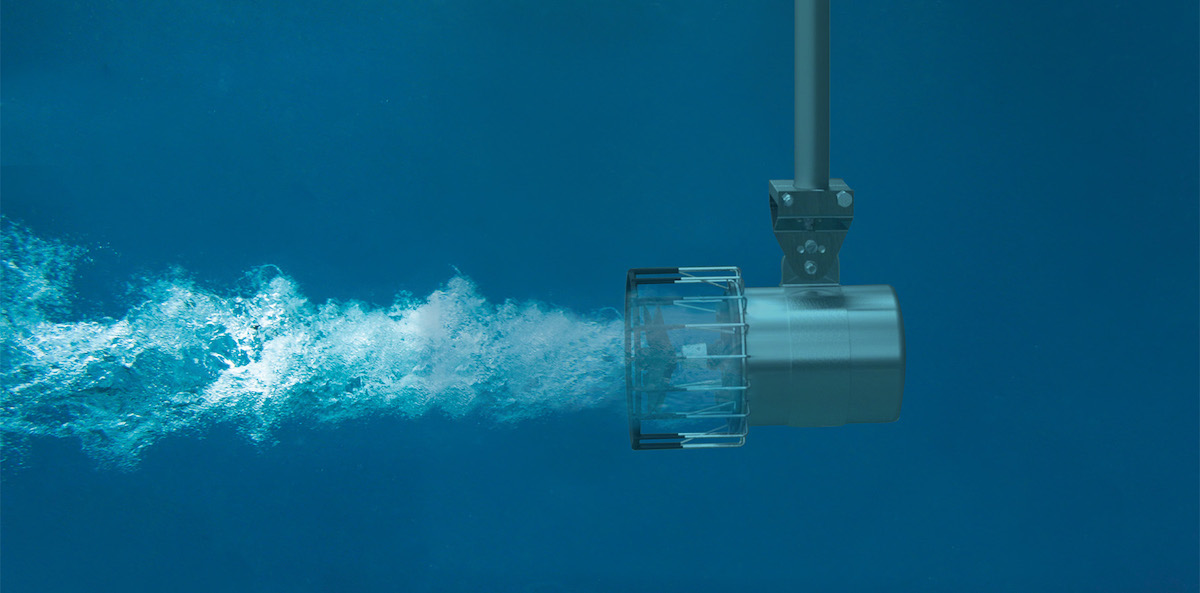

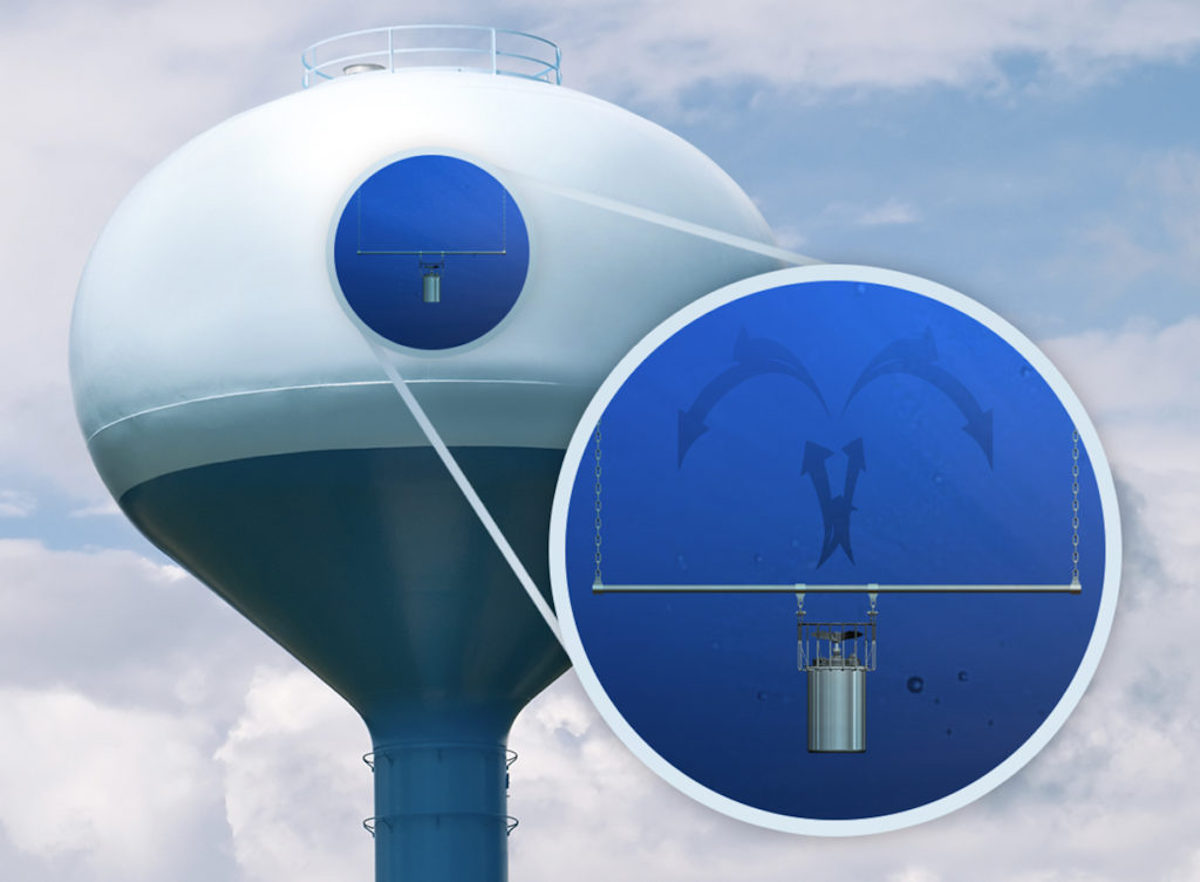

10. Keeping Your Tank Filled During Mixer Installation

The real beauty of installing a Kasco CertiSafe Mixer is that all models are specifically designed by Kasco engineers, who have been designing submersible mixing systems since 1968. Our mixers are designed to be installed without needing to drain the tank and waste potable water!

The best active mixing systems for potable water tanks are designed for effectiveness, safety and durability. Kasco’s CertiSafe Tank Mixer for potable water is certified and tested to strict NSF/ANSI 61 & 372 standards and ETL Listed to UL and CSA standards. This tank mixer is easy to install, and can be mounted using a floor, suspension, or pipe mount. If you need help designing your active mixing system, Kasco’s CertiSafe team can answer your questions and provide design support to bring you project from concept to completion.

About Us or CTA Section

Testimonials

-Seth

-Seth

-Seth