How Active Mixing Increases Tank Longevity and Improves Water Quality

Introduction

Your municipal water tanks are valuable assets. They represent both a sizable capital investment and a crucial barrier in your potable water supply. To prevent costly problems, water tanks need to be inspected regularly and operated properly to maintain tank integrity and water quality.

American Water Works Association, or AWWA, has produced a standard for steel water tanks.¹ The standard recommends that operators visually inspect tanks regularly, monthly at a minimum. Every three years, again at a minimum, tanks should be drained, washed out, and professionally inspected. Inspections must assess safety and security issues, structural and coating condition, and obvious sanitary concerns (e.g. biofilm/sediment build up).

But what about between inspections? Problems arise that have the potential to impact not only

water tank integrity but also water quality. Problems such as:

- Water tank damaged by freezing and corrosion

- Increased water age and reduced chlorine residuals

- Increased risk of nitrification in chloraminated systems

- Increased production of disinfection byproducts

Let’s first examine these problems in more detail and then how adding one component to the system has the potential to solve them all.

Problems in Un-Mixed Water Tanks

Static water conditions in a water tank cause issues in all seasons. In winter, static water freezes, damaging the tank and its coating. In summer, stratification can impact both the tank and water quality.

Winter in Un-mixed Water Tanks

During winter, ice forming in a water tank scrapes interior tank fittings and coatings as the water levels change from daily fill and drain cycles. Water freezes in a tank due to three main causes:

- Improper water tank specifications

- Compromised Overflow

- Static water conditions

Of these problems, the tank design specifications are clearly beyond the operators’ control.

Overflow issues tend to be solved with proper maintenance. Static water conditions, however,can be impacted by operational measures. Freezing can cause:

- Internal piping and overflow breaks

- Ladders to be pulled out by ice, leaving a hole at the point of attachment

- Hoop stress loads on the steel and seams from expanding ice

- Ice damage to the tank lining, allowing corrosion

Summer in Un-Mixed Water Tanks

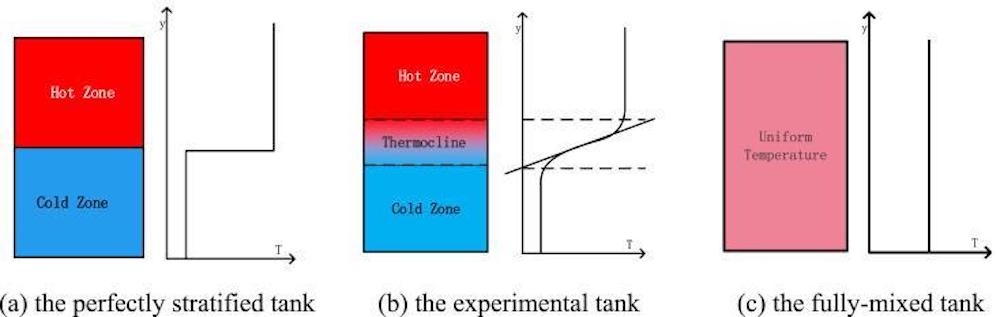

In summer, the water in an unmixed water tank begins to warm. The warmer water rises to the top. When newly treated denser, cold water enters, it doesn’t mix with the warmer water in the tank. Instead, the cold water will fall to or remain at the bottom of the tank water column, depending on the inlet structure. This cold bottom water can also be the first to exit the tank, leaving the bulk of the warmer top water unmixed and unused. This process, called stratification, causes many problems in water tanks (see figure 1²).

Increased Water Age and Reduced Chlorine Residuals

Thermal stratification leads to chemical stratification that can seriously compromise water quality. The upper layer contains the oldest, warmest water with low disinfectant residuals. This can lead to bacteriological contamination and high concentrations of disinfection by-products. The warm conditions at the air-water interface on the interior sidewall allows biofilms to prosper. This increases organics in the water and contributes to corrosion of the tank wall.

Figure 1

Increased Risk of Nitrification in Chloraminated Systems

Chloramine, formed by reacting aqueous chlorine with ammonia, is one of the longest-lasting water disinfectants. However, it will decompose over time, generating free ammonia in the process. This decomposition accelerates when water temperatures exceed 60° F. With ammonia liberated, ammonia-oxidizing bacteria multiply, converting NH3 into nitrites and nitrates. The production of nitrite/nitrate represents a loss of chlorine residual as well as causing taste and odor issues.

Increased Production of Disinfection Byproducts

In a stratified water tank, several factors can lead to high organic loads in the water. Reactions of chlorine with organic matter lead to the formation of disinfection byproducts (DBPs). DBPs can be detrimental to human health and are regulated under the Safe Drinking Water Act.³

Mixing Systems for Water Tanks

Passive Mixing Systems

Passive mixing systems seek to mix water without additional energy-using infrastructure. Although ‘passive’ with regards to the water tank itself, some designs rely on operation actions and most put an extra burden on pumps in the distribution system.

Operators can force high turnover in tanks in an attempt to mix the water. However, deep cycling, even up to 60%, can still leave the water thermally stratified in the top layers. Not only does high turnover not adequately mix the tank, it comes with high operational costs.

In a traditional water tank, the water enters and leaves the tank through the same pipe. To increase passive mixing, tanks can be designed or retrofitted with a separate inlet and outlet. The inlet is generally higher in the tank to encourage mixing of fresher, colder influent water with older, warmer water in the tank.

Some passive mixing systems use a complex series of pipes and nozzles to inject the incoming water throughout the tank. These systems are large, expensive to install and maintain, and can still result in incomplete mixing.

Effectiveness

Reliant on the momentum of influent water, passive systems don’t mix water once the tank is full or during the drain cycle. And water tanks can quickly re-stratify once the infill has stopped. Passively mixed tanks can re-stratify both thermally and chemically within four hours after pumping ceases.

Although called “passive”, these mixing systems do utilize the distribution pumps and the additional back pressure exerted by nozzles force those pumps to work harder. This requires more power and increases maintenance costs.

Cost of Retrofit / Installation / Maintenance

Passive mixing systems can involve the installation of multiple nozzles and piping, which can be very expensive to begin with. You will also have more surface area (and bolts and corrosion points) to paint, coat and maintain inside your tank, which requires extra time, labor, and money. Even separating the inlet and outlet is a costly tank retrofit.

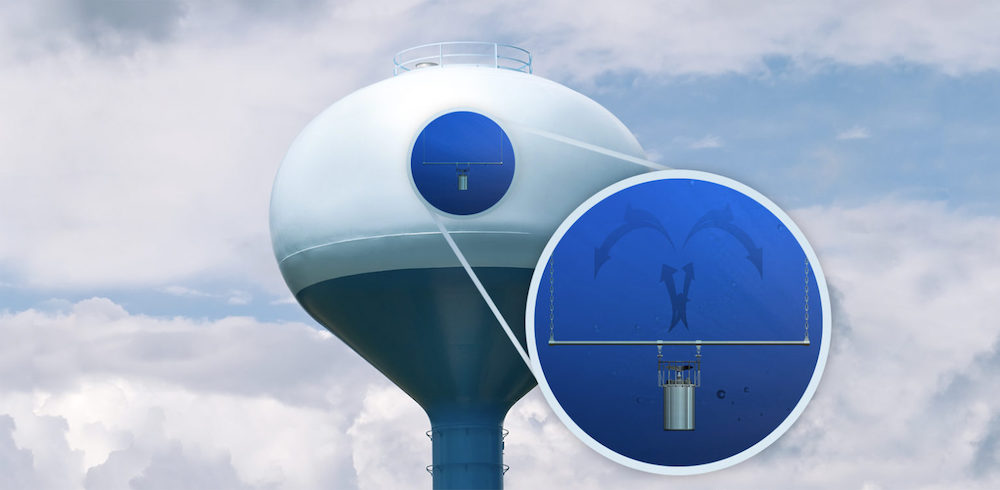

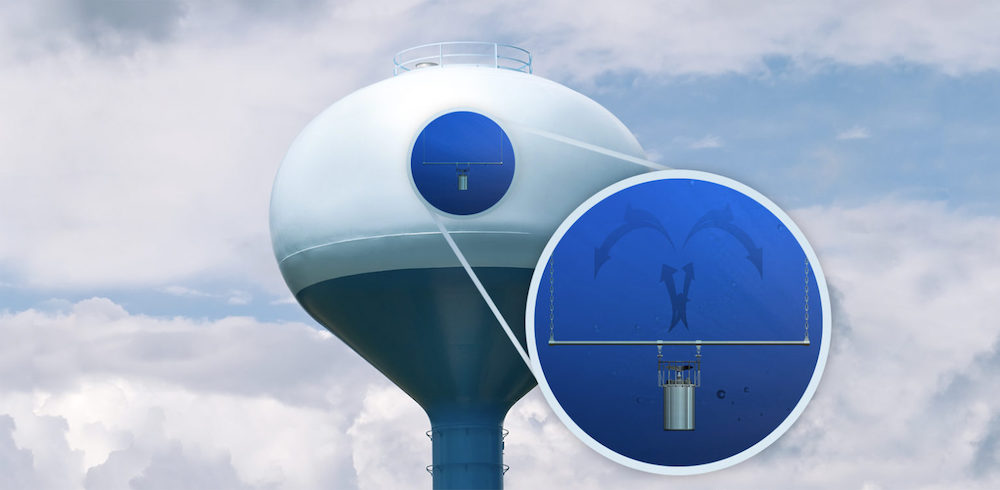

Active Mixing Systems

Active mixing systems use a motor-driven impeller to keep water circulating inside the tank continuously, regardless of how full the tank is. They’re smaller and more sustainable than passive mixers and they provide operators with more mixing power, independent of drain and fill cycles. Active mixing systems are less expensive, easier and faster to install, and can be easily removed for tank inspections and maintenance.

Effectiveness

One way to judge effectiveness when comparing mixing systems is to look at blend cycles. The blend cycle is the time it takes to mix the water to a homogeneous temperature during the fill cycle. For instance, if it takes two hours to refill the tank, then the active mixer needs to be able to blend the new water with that already in the tank in two hours.

By definition active mixers have moving parts. However, maintenance requirements can be minimal, and their energy footprint is generally low.

Ease of Retrofit / Installation / Maintenance

Active mixing systems are easy to install in new or existing tanks, without using cranes, drilling holes, or draining the tanks. They can be mounted using a floor base, or suspension or pipe mounts. They’re easily removable for tank inspection and maintenance.

Benefits of Active Mixing in Water Tanks

Active mixing in water tanks provides benefits all year round. In winter, active mixing prevents ice formation. In summer, stratification never has a chance to develop.

In winter, active mixing prevents damage to water tanks. For water tanks in cold climates active mixing systems provides several benefits:

- Significantly reducing physical damage from ice formation

- Minimizing the potential for bio-film growth and disinfection by-products

- Improving overall water quality

In summer, active mixing eliminates stratification. By eliminating stratification, active mixing has positive impacts on water age and disinfection and reduces the risks of nitrification and the formation of disinfection byproducts.

Reducing Water Age and Residual Loss

An active mixing system results in homogeneous water quality throughout the tank, reducing water age. It minimizes or eliminates biofilm growth by continuously delivering disinfectant to all interior surfaces. This in turn minimizes disinfectant demand. It also reduces organic contamination from microbial growth.

Reducing Nitrification Risk in Chloraminated Water

Although active mixing reduces nitrification risk in water tanks, it doesn’t solve the issue completely. Nitrification in chloraminated systems a complex issue, but complete continuous mixing is crucial to its management. If disinfection boosting is also required, it’s much more effective and efficient in a well-mixed water tank.

Reducing Production of Dbps And Potential For Biological Contamination

Uniform water quality, in particular maintaining effective chlorine residuals, eliminates the risk of biological contamination. The reduced biological activity leads to reduced organic matter in the water and therefore the formation of disinfection by-products.

CertiSafe Mixers Solve Problems in Water Tanks

Active mixing provides for a proactive rather than a reactive approach to controlling water quality in the distribution system. Active mixing improves water quality and reduces water quality complaints. Active mixing provides a complete mix of the water by:

- allowing consistent chlorine residuals throughout the tank

- elimination of thermal-stratification

- reduction in bio-film growth

In the unlikely event that the chlorine or chloramine residual needs adjustment in the water tank, an active mixer allows for a complete mix of the added chemicals.

Kasco provides an NSF-61 approved cost-effective solution to your tank mixing requirements. Of the active mixing options available, Kasco’s CertiSafe™ Municipal Mixer for potable water is top of the list due to its superior design, outstanding effectiveness, operational efficiency, and ease of installation

Conclusion

Your municipal water tanks are valuable assets, both in terms of your capital investment and in terms of your commitment to delivering quality water to your community. Regular inspections by operators and periodic inspections by professional engineers will help protect your asset.

However, even with frequent inspections, regular maintenance, and the best operators, problems can still arise. These problems can be caused by freezing temperatures in winter and high temperatures in summer. However, as we have seen, there is a solution: active mixing.

The best active mixing systems for potable water tanks are designed for effectiveness, safety, and durability. To solve problems in your water tanks, learn more about Kasco’s CertiSafe Tank Mixer.