Written by Lucy Allen (Kasco Municipal Business Development Manager), Thom Tackman (Certified Water Operator) & Scott Ham (Manager at Silver Creek Water Corporation).

This article is an in-depth examination at how Silver Creek Water Corporation performed a case study to test, evaluate and improve water quality in their storage tanks. The goal of the study was to use simple testing techniques to determine if tank mixing does improve water quality to the customer tap.

Introduction

SCWC is in Sellersburg, Indiana, and many of the residents’ work in nearby Louisville, Kentucky. SCWC purchases water from Indiana-American Water Company and does not treat the water supplied to them. The SCWC is governed by a Board of Directors who take great pride in their facilities and their desire to supply high-quality water to their customers.

The water distribution system consists of five water storage tanks and four water booster stations along with 155 miles of distribution piping. The water storage tanks vary in size and volume ranging from 151,000 gallons in a standpipe tank to 2.2 million gallons in an in-ground concrete tank. Water is supplied through two-meter vaults.

Maintaining a chlorine residual to the customer tap has not been a major issue but there have been times when the chlorine residual would change, especially in the summer months. Disinfection by-products have never exceeded State and Federal standards; however, they did seem to rise and fall for reasons unknown at the approved sample points.

IMPROVING WATER QUALITY IN THE WATER STORAGE TANK

Scott Ham is the Corporation Water Manager at SCWC. After observing these changes within the water tank, he desired to understand why water quality was changing in the distribution system and what he and his team could do to minimize those changes.

During an annual water conference, a SCWC board member came across the Kasco booth and asked Scott to look at the Kasco CertiSafe Active Mixer.

Scott had previous experience with active and passive mixers as both were installed and operating in two of the five water storage tanks. The Kasco team reviewed the application and recommended to Scott’s team a ¾ hp, 120-volt Kasco CertiSafe floor mount mixer with a control panel. Temperature probes were provided at no cost by Kasco so that temperature profile testing could be completed. The overall easy installation of the mixer made the testing phase manageable for Scott’s team.

TESTING MIXER PERFORMANCE

SCWC Team installed a mixer in the new Fairview Knob 2.2-million-gallon water tank. The mixer, power cable, and control panel arrived a few days after the order was placed, and with help of a local electrician, the mixer was installed through the center vent of the storage tank. Installation was easy and completed soon after.

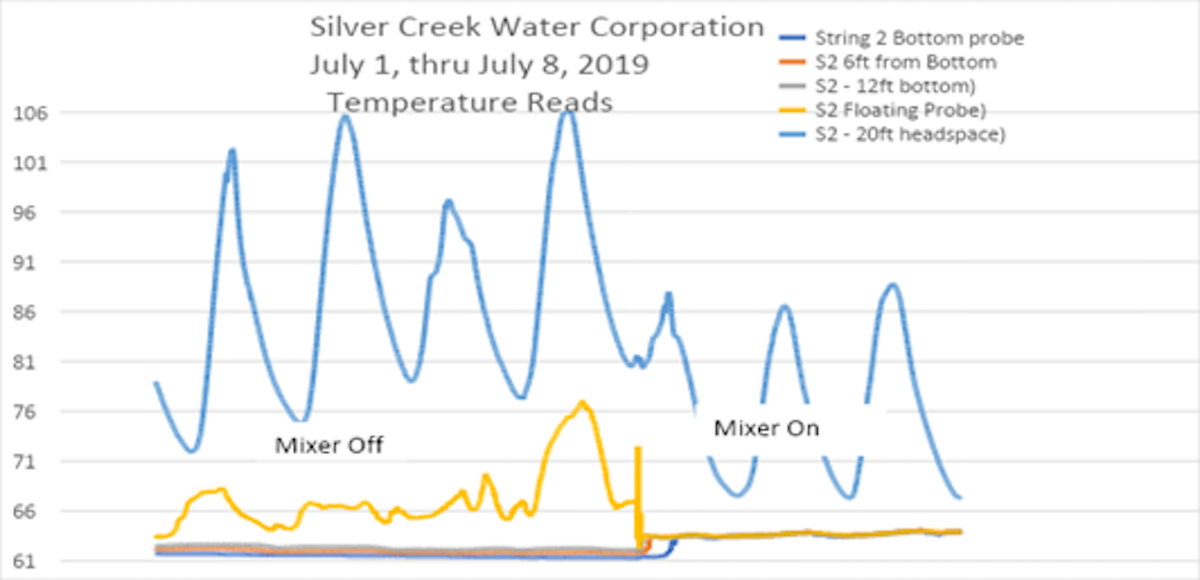

A few weeks after installation, a temperature string supplied by Kasco arrived and was installed in the tank hatch away from the mixer. The test ran for several weeks and the mixer was turned on and off during the test period to see the results. During the temperature testing, chlorine odors were readily apparent when the mixer was off and were not detectable when the mixer was running (figure 1 below).

Figure 1: Temperature readings taken in the water tank between July 1 and July 8, 2019.

In March 2020, Kasco team members Lucy Allen and Thom Tackman visited with Scott to discuss additional testing at the 2.2 MG Fairview Knob Tank during a second round of tests. The next test would be expanded and would include both chemical and thermal stratification along with sampling and testing for disinfection by-product formation.

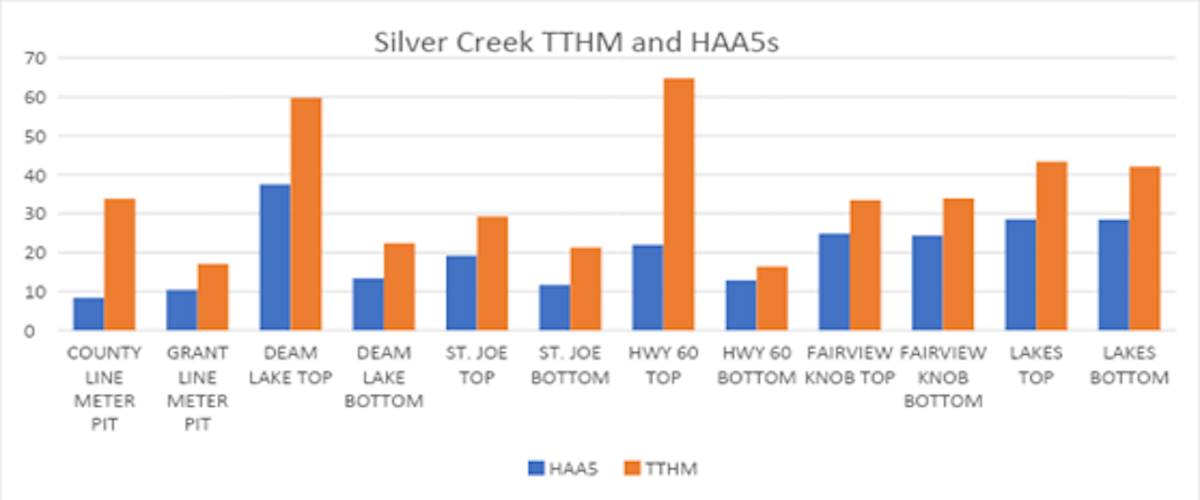

Step one of the tests was to make sure that all the corporation safety standards were met, so they first trained on climbing the elevated storage tanks to make sure everyone had the proper training and safety gear. The second step was to determine what testing equipment was required and locate a lab to run TTHM and HAA5 samples (reference figure 3). The samples were pulled from the top and bottom of all five reservoirs. The third step was to coordinate the tank sampling with the temperature probe testing and document the readings.

Testing began in June and was completed in August of 2020. SCWC Team documented the results of their chlorine residual and temperature testing and with help from a neighboring laboratory the TTHM and HAA5 samples were tested. The test results showed that the two tanks with active mixers had similar free and total chlorine residuals in both the top and bottom of the tanks regardless of water age. The water temperatures were nearly the same in the top and bottom of the tanks and disinfection by-product levels were very close in both the top and bottom of the tanks (figure 2, Fairview Knob and Lakes Tank Data). In short, the active mixers were meeting their intended purpose and also influenced lower air temperatures in the headspace of the two tanks (figure 2).

Figure 2: TTHM and HAA5 data.

The testing results in the tanks without the active mixers tested quite different. The temperature difference varied by 10-degrees from the top to the bottom of the tanks and little or no measurable chlorine residual was tested at the top of the tanks. SCWC operators were quite surprised by the chlorine results measured at the top of the tanks and completed multiple tests to verify the residual results.

TTHM and HAA5 results were even more revealing. While all of the tanks had been thoroughly cleaned and inspected within the past 12 months, the disinfection by-product levels were three times higher in the top of the tanks as compared to samples taken from the bottom of the tanks. Test results concluded that TTHMs and HAA5 levels were much higher in the top of the tanks when not actively mixed (Figure 2, St. Joe, Deam Lake & Hwy 60 Data).

Active Mixing to the Rescue

Based on testing conducted by SCWC Team, the Board of Directors approved the purchase of three additional Kasco CertiSafe™ active mixers. When work is completed, all five of the water tanks will have active mixers with an equipment cost of less than $10,000 per tank.

Scott Ham has a motto that he freely shares, “Don’t tell me what I can’t do, but rather let me show you what we will do together!” The SCWC Team has successfully demonstrated Scott’s “We Can Do It Together” attitude by completing the equipment installation and testing as a team. The data they collected clearly shows the benefits of active mixing. Their efforts have provided a cost-effective water quality improvement solution at the customer’s tap, using simple testing techniques.