By: Arik Jones, Water Superintendent at Rye Water District & Lucy Allen, Kasco Municipal Development Manager | March 23, 2023

The Rye Water District in New Hampshire serves a population of 5,500 residents, with 1,702 connections to the water supply. Every day, the district pumps 1.2 million gallons of water into three storage tanks. From there, the water is distributed to residents.

In the northern United States, water districts have to deal with the dual challenge of providing a reliable supply of domestic water to their residents, while also preventing the formation of ice within water tanks over the winter months. Ice formation can lead to a range of issues including water pressure fluctuations, increased maintenance costs, and the risk of structural damage.

These issues can be resolved with the use of the Kasco CertiSafe™ mixer. This powerful, active tank mixer is fully submersible and designed specifically to effectively mix stored water throughout the tank. This eliminates thermal stratification, preventing damage and corrosion due to ice formation.

Discover more about how the Rye Water District uses the CertiSafe mixer to reduce the buildup of ice within their tanks, resulting in lower maintenance costs, reduced risk of structural

damage, and a consistent, safe water supply for the residents they serve.

The problem: delivering a reliable water supply in all weather conditions

The Rye Water District aims to provide a consistent supply of high-quality, potable water to the community. To do so effectively, water operations must maintain the correct level of water pressure within the system.

To counteract water pressure issues within their system, the Rye Water District pumps water into storage tanks to deliberately and strategically maintain the correct levels of pressure. The elevation of water in the tanks drives water through the city’s pipes and into residents’ homes. But during the winter, the district faces an additional challenge of ice formation within the

tanks. When ice forms in a water tank, pressure in the system can be adversely affected and residents can experience issues with their water supply as a result. Water operators know that to guarantee a consistent supply of water over the winter, the tanks need to be managed properly.

In addition to adversely affecting water pressure, ice formation also leads to two other major problems: increased maintenance costs and the risk of structural damage to the tanks.

Increased maintenance costs

When ice forms within a water tank, it can prevent routine maintenance from being carried out. In 2009, the Rye Water District experienced issues when planned maintenance to recoat the interior of a tank had to be delayed. Due to ice forming within the tank, a specialized diving team had to spend a week breaking up the ice and removing it. This resulted in a lot of additional work and needing to find the funds to complete it before recoating work could commence.

Ice can also cause significant additional maintenance costs when it damages the tank as it scrapes along the sides. This not only damages the interior of the tank but can also damage internal maintenance ladders.

Risk of structural damage

In a worst-case scenario, ice formation can cause a water tank to burst. This not only poses a threat to the local community but creates physical damage to the water tank, leading to costly financial implications.

Because the water within the Rye Water District’s tanks is also used for firefighting, ice prevention is crucial. When ice freezes across the surface water of a tank, it also adheres to the edges of the tank. When a large volume of water is rapidly pulled out of a tank during a firefighting operation, this can leave a ‘cake’ of ice hanging at the top. This is a very dangerous situation that can cause irreparable structural damage if the ice breaks and falls. But it can be prevented.

Arik Jones, Superintendent for the Rye Water District, recognized that implementing a more effective strategy for preventing ice formation would help solve these problems.

“We knew that ice was forming in our tanks,” said Jones. “Was it causing an immediate and urgent problem at that moment? No—but I knew that ice would mean trouble down the road, so we decided to act now.”

Kasco’s solution: active mixing for ice prevention combined with regular tank maintenance

The formation of ice in water tanks can be prevented by using a combination of ‘active mixing’ and regular maintenance. Active mixing circulates the water at regular intervals using a motor-driven impeller. This pulls warmer water from the bottom of a tank into the upper layers, which get colder during winter, and prevents ice from forming.

Kasco has over 50 years of experience designing and building pumps in a wide variety of environments, with the CertiSafe mixer being purpose built for potable water applications. The CertiSafe active mixing units are designed for reliable performance in all weather conditions. The mixer turns water to effectively prevent ice formation within only few hours of installation.

“I knew mixing would prevent ice formation and save us a lot of money in the long run,” continued Jones. “I considered [the CertiSafe mixing unit] a very worthwhile investment.”

In addition to installing a high-performing CertiSafe active mixer, regular maintenance checks are important for ensuring the unit is functioning correctly. To complete these checks, the Rye Water District contracted expert asset management company Underwater Solutions. With specialized industry expertise, plus safety certifications to meet Occupational Safety and Health Administration (OHSA) standards, Underwater Solutions is able to provide the Rye Water District with the peace of mind that its assets are operating correctly.

Delivering reliability

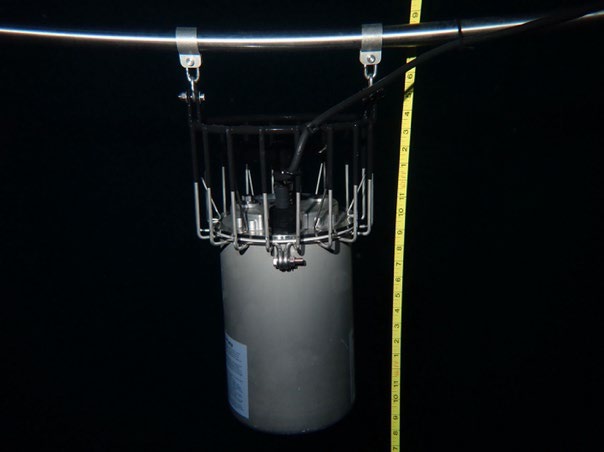

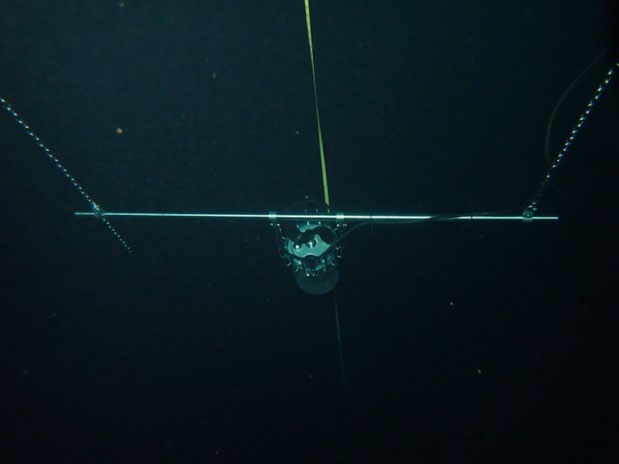

Once the Rye Water District had selected the Kasco CertiSafe NSF 3400HC61 240v 3/4hp mixer, they began the process of installation. This mixer was installed by Underwater Solutions at the Breakfast Hill tank, a welded steel tank with a 1.2MG capacity, with a height of 100 feet and a diameter of 45 feet, located at Lafayette Road, Rye, New Hampshire.

Installation took only one day and involved removing the center roof vent and installing the mixer. Divers then attached chains near the vent and set the mixer at the correct level for optimum operation, using the SM100 suspension mount. This was combined with the Kasco Advanced SCADA control panel for remote operation and monitoring.

The benefits of installation were quickly apparent according to Jones.

“I waited until it got cold and when I inspected the tank in January, I couldn’t believe the change,” said Jones. “There was a huge difference in ice formation. Any cost of installing and maintaining the mixer was minimal compared to the alternative—continuous repairs, potential damage to customers’ homes from water pressure issues, or people getting sick from contaminated water.”

Active mixing with the Kasco CertiSafe Tank Mixer

Ice prevention isn’t the only benefit of active mixing. This technique can also solve water quality

issues including:

- Eliminating thermal stratification

- Chlorine residuals

- Improving water quality

- Reducing sediment accumulation

- Lowering the rate of disinfection by-products

- Eliminating chemical stratification

- Reducing differences in water taste and odor

CertiSafe mixers come in multiple sizes, with NSF approval for potable water tanks as small as 20,000 gallons and models designed for mixing tanks over 1 million gallons. This high-performance, low-cost active tank mixer is fully submersible up to a depth of 50 feet, easy to install, and can be mounted using a floor, suspension, or pipe mount. Kasco sets the standard for world-leading water quality solutions, backed by unrivaled support and expertise.

Contact the CertiSafe sales team for more information at: kascomarine.com/about/contact/.

Case Study: Clean Water in Searcy, Arkansas

Case Study: Clean Water in Searcy, Arkansas

Mixing Case Study on Water Quality in Storage Tanks

Mixing Case Study on Water Quality in Storage Tanks

10 Reasons to Specify an Active Mixer

10 Reasons to Specify an Active Mixer