Understanding the Impacts of Fat, Oil, and Grease in Municipal and Industrial Lift Stations

By: Kasco Staff | Aug. 24, 2023

____________________________________________________________________________________________

Bring Wastewater Operational Efficiency Up and Lift Station Maintenance Costs Down with Kasco’s New HydraForce Lift Station Agitator

Maintaining lift stations is crucial for ensuring wastewater process operational efficiency from the source to the treatment plant. One of the major challenges faced by wastewater process operators is the accumulation of fats, oils, and grease (F.O.G.) within these stations. Neglecting lift station maintenance can lead to severe consequences such as sewer line corrosion, foul odors, blocked pipes, and improper treatment and discharge of pollutants. In this article, we’ll explain what F.O.G. is and where it originates, the dangers of leaving F.O.G. untreated, and how the HydraForce Lift Station Agitator prevents buildup and decreases operational issues and equipment failure.

What is F.O.G.?

Fat, oil, and grease, often referred to as FOG, or FATBERG, are a common trio of substances that come from the cooking and food preparation process. When we cook food using butter, oil, or meat drippings, some of these substances are washed down drains, accumulating in sewer system lift stations and causing blockages. Prior to arriving at the lift station, F.O.G passes through a series of screens and membranes that are meant to filter and remove the harshest of the scum. However, the issue is getting harder to control as more restaurants open and the population increases.

The Problem: When F.O.G. and Lift Stations Meet

Lift stations commonly develop several layers of F.O.G buildup that can create a ring around the lift station interior and accumulate on other internal equipment such as pumps, chains, floats, sidewalls, etc. This can cause reduced operational capacity, mechanical problems, plugging, interrupt service and cause terrible odors if left untreated.

The cost to remove F.O.G from lift stations can “wipe-out” maintenance budgets within months or even days, often topping $100k. Peak hours of the day are especially hard to prevent F.O.G. buildup and odor issues. Sending untreated F.O.G. down the line to the treatment plant can cause poor plant performance and be more expensive to treat than if it were taken care of earlier at the lift station.

F.O.G. Challenges and Solutions

It’s essential to properly treat F.O.G. before it enters the wastewater treatment plant. Commercial kitchens can use grease traps and homeowners can pour it into the trash instead of the sink. To combat F.O.G. that reaches lift stations, it’s important to treat it right away and implement a long-term solution for maintenance.

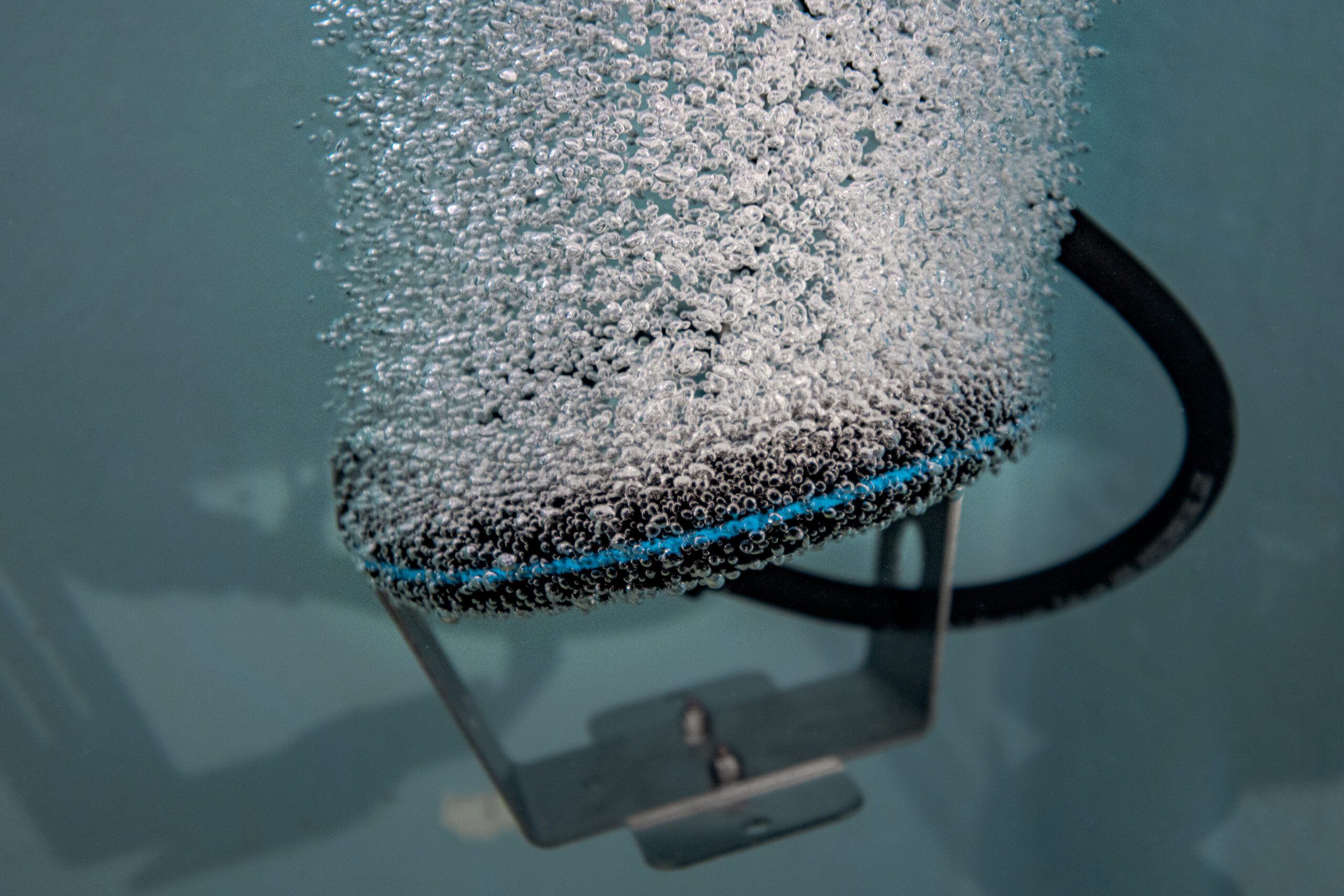

Kasco offers our HydraForce Lift Station Agitator as a simple, effective, and cost-efficient way to create a reliable collections system. Using a constant flow of air bubbles from a suspended diffuser, F.O.G layers are broken up and prevented from reforming. With consistent movement and flow within the lift station, the easy-to-install diffuser system ensures even dispersion of F.O.G., minimizing the risk of accumulation. This allows pumps and pipes within the lift station to remain unclogged, while keeping solids in suspension to be sent to the treatment plant.

The F.O.G. is Lifted

If left untreated, F.O.G. can cause major headaches for treatment plant employees and area residents. Decreased operational capacity, increased maintenance costs, FOG layers and blockage cap formation, and equipment failure are among the top issues.

Take control of your lift station and treatment plant operational efficiency and maintenance costs by installing Kasco’s HydraForce Lift Station Agitator.