High heat and excess dust are key factors in reduction of compressor life. See how Kasco Large RobustAire™ Diffused Aeration Systems tackle these issues.

Across the industry, diffused aeration systems use roughly the same design for the compressor cabinet. This includes a square box, compressors, fans, and filters – until now. Kasco recently introduced a newly designed larger cabinet that’s been completely redesigned and reengineered from the inside out, resulting in a system that operates at much lower internal temperatures, is easier to maintain, and lasts longer.

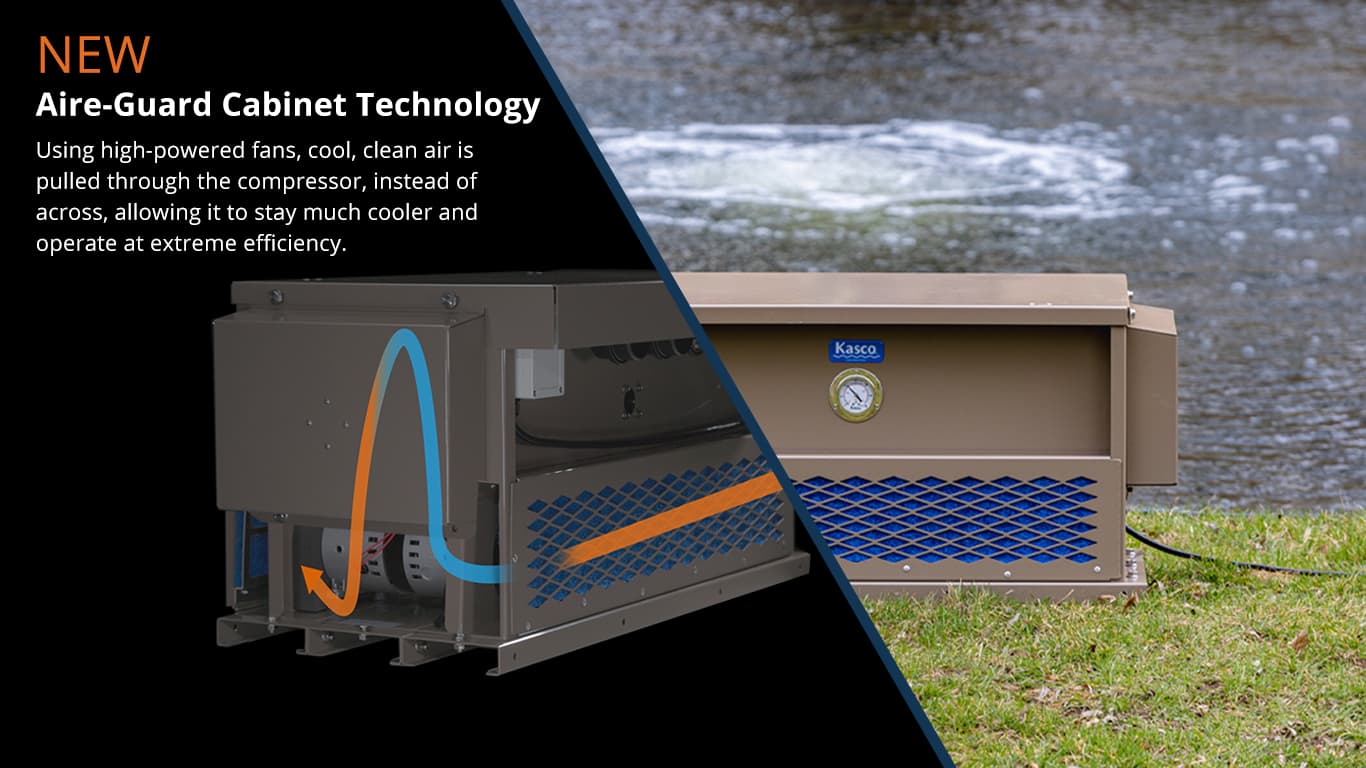

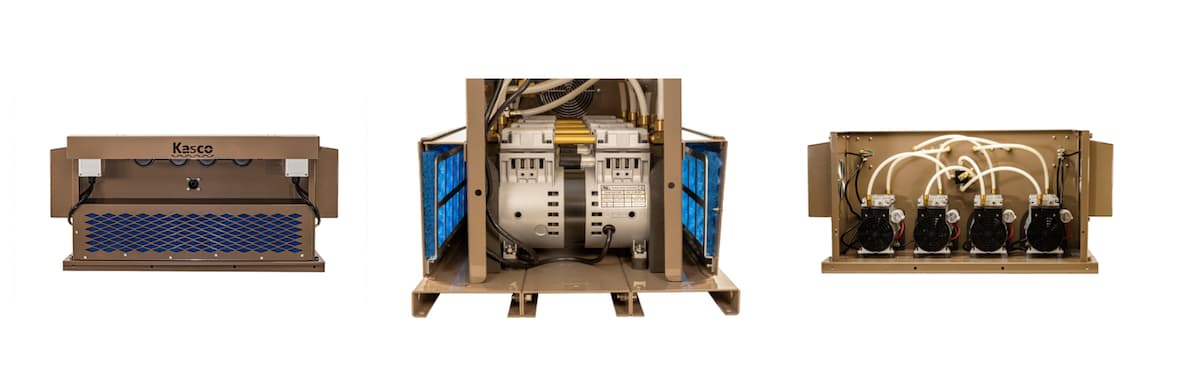

From the outside, these new cabinets feature visual maintenance indicators, external glycerin-filled pressure gauges, air filters, easy-to-remove panels, and a color that seamlessly blends with the environment. But it is what’s inside the cabinet that truly sets our new systems apart from the rest.

Typical Diffused Aeration Systems

Diffused aeration systems are made up of diffusers that sit at various locations on the bottom of the water body. Weighted air lines run from compressor cabinets on the shore. Traditionally, these cabinets have cooling fans on one end and louvers, or vents, on the other. The fans bring in unfiltered, dirty air from the outside. They then blow it over the compressor and out of the cabinet. Too often, cooling fans are undersized resulting in high internal temperatures. In addition, dirt and dust can easily find its way inside. The result is a messy cabinet interior.

Heat & Dust: A Compressor’s Downfall

While the typical set up of these systems does in fact move air through the cabinet, the design soon falls short. This is because it does not address the most common reasons for compressor failure: heat and dust.

HEAT

Compressor motors generate heat on their own through normal operation. Couple this with high outdoor temperatures, extended periods of operation, or even dirty air filters, components can easily become damaged. As a result, the run time of the compressor and diffused aeration system is compromised. The images below show thermal readings of a compressor inside a cabinet using AireGuard Cabinet Technology (left), and a compressor inside a cabinet not using AireGuard Cabinet Technology (right). The readings show an almost 40° F difference in temperature.

Compressor heat with (left) and without (right) AireGuard Cabinet Technology

DUST

Dust, debris, and dirt are a compressor motor’s worst nightmare and quickly causes damage. If left long enough, it can then act as a layer of insulation causing the system to run even hotter. Not only does dust and debris increase heat, but it can easily get inside critical connection points, gauges, and air lines. Therefore, system performance quickly diminished if dust is allowed into the system and cabinets are not regularly cleaned.

Kasco’s New Large Systems With AireGuard Cabinet Technology

Designing a system that would account for heat and dust was the most important aspect of the project. We knew we needed a system that would successfully operate in harsh desert environments, as well as areas prone to long exposures of excessive heat, high wind, and unrelenting dust.

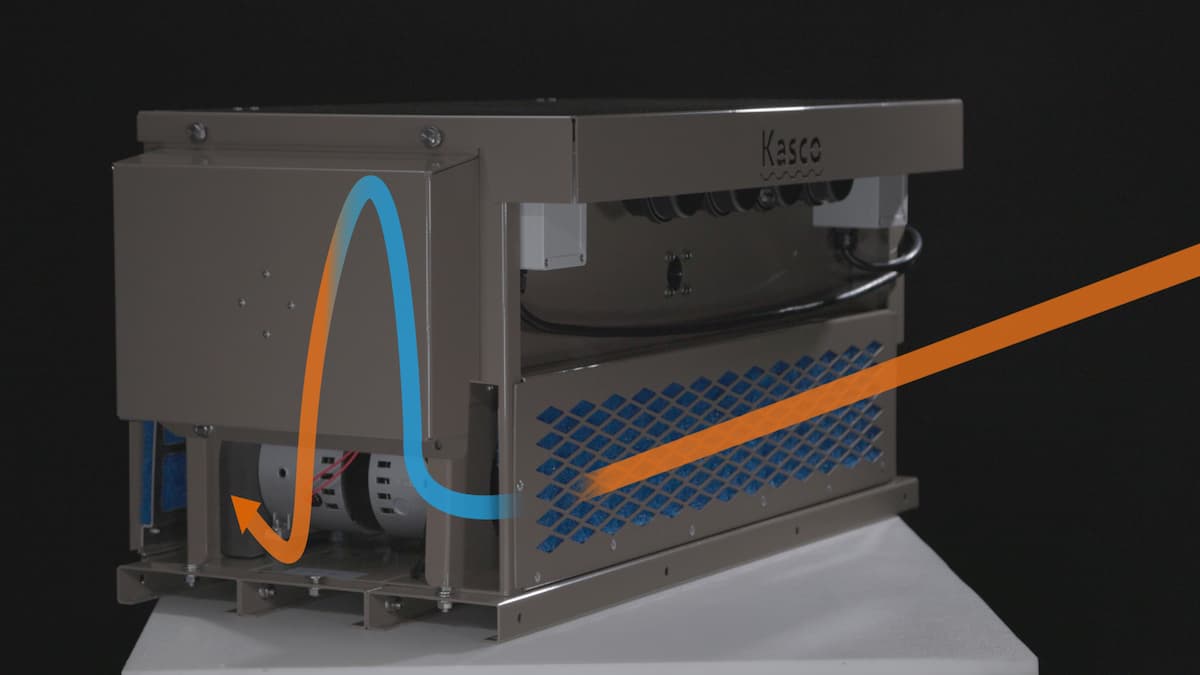

The result is a cabinet and airflow technology the industry has never seen. No cooling fans, and no louvers, but with additional layers of external filtration. AireGuard Cabinet Technology (patented) allows air to immediately pass through an external filtration layer that removes dust and debris. This clean air is then pulled through the compressor motor, instead of across. This allows it to stay much cooler and operate with extreme efficiency. Compressor motors will stay much cooler and dust and debris filter out before entering the cabinet.

With this design, internal testing has shown a reduction of 40 degrees inside the cabinet over competitive units. Additionally, flow simulation software shows airflow inside the cabinet has doubled.

Setting the New Standard

All in all, with Kasco’s new Large RobustAire™ systems featuring AireGuard Cabinet Technology, diffused aeration systems are no longer defined by short compressor lifespans. By understanding airflow and the most common failure points, Kasco now offers a system that will withstand the harshest environments as well as deliver exceptional water quality results.

To learn more about these systems and the multitude of features and benefits, visit the RobustAire web page.

If you have any questions, please email us or call 715-262-4488.

Interview With The Engineer: Large RobustAire™ Systems

Interview With The Engineer: Large RobustAire™ Systems

Innovative Airflow is the Center of New Larger RobustAire™ Systems

Innovative Airflow is the Center of New Larger RobustAire™ Systems

Interview with the Engineer - Medium RobustAire™ Systems

Interview with the Engineer - Medium RobustAire™ Systems